Polypropylene is a synthetic, man-made material classified as a plastic within the polyolefin group of hydrocarbon polymers and plastic products similar to polyethylene. Polypropylene (abbreviated PP) is a highly versatile plastic widely used as a structural, fibrous or textile type material within an extensive collection of modern items and industry applications.

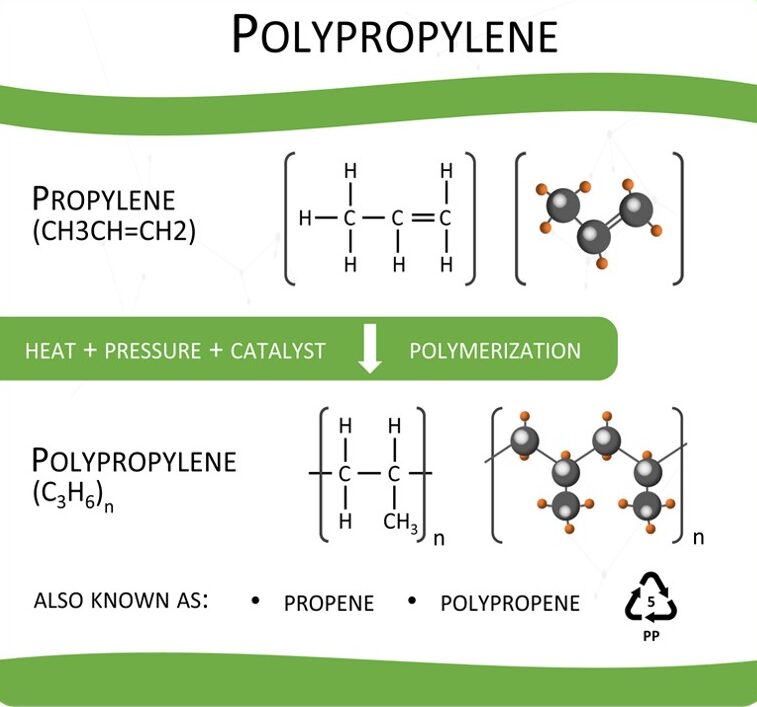

Polypropylene belongs to the thermoplastic division of synthetic plastics meaning it softens rather than burns as temperatures near the melting point and allows the plastic to liquify for use in production and recycling activities. Polypropylene products are often labeled with the #5 resin code and symbol that serves as a material identifier and indicator of the product’s recyclability.

When compared to other plastics, PP has an increased molecular crystallinity, flexibility, physical toughness, chemical tolerance, and resistance to high and low temperatures. At its most basic level, polypropylene is a large molecular compound constructed from repeating units of individual propylene monomers linked together by chemical reaction.

Propylene, also known as propene, belongs to the olefin group of simple double-bonded hydrocarbons and can be represented in chemical formula as CH2=CHCH3 or C3H6. These individual propene molecules have their bonds broken then reconnected to formulate the polymer chain known as polypropylene. Polypropylene is represented chemically as (C3H6)n, where “n” indicates its continuity depending on the specifics of its manufacture and its intended use.

How is Polypropylene Made

Polypropylene, similar to PVC, polyethylene and nylon, is manufactured from a chemical by-product that originates from the refining process used to turn crude oil, coal and natural gas resources into modern combustible fuels. This hydrocarbon cracking process also produces various chemical fractions, waste materials and gasses including naphtha, ethylene, and propene amongst others. The propene / propylene gas generated can then be isolated and used in polymerization to form the compound polypropylene.

Polymerization of propylene into polypropylene is often performed by bubbling gaseous propene through liquid propene. The liquid propene media contains catalysts that serve as active sites to collectively bind propene molecules and form the PP polymer chain. Polypropylene polymerization is often performed at temperatures between 140 – 176°F (60 – 80°C), at pressures from 30 – 40 atm (440 – 588 psi), and uses the Ziegler-Natta catalyst.

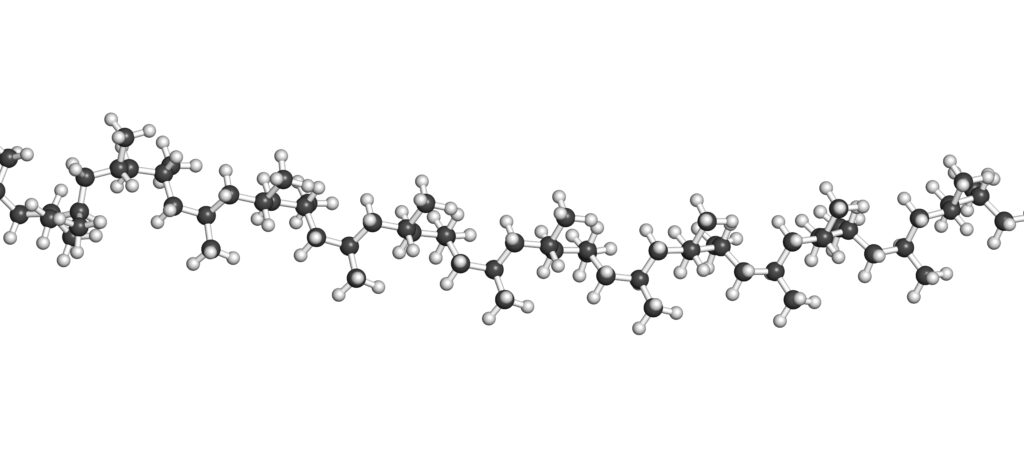

Resulting polypropylene compounds can be fabricated as either isotactic or syndiotactic and further as either a homopolymer or copolymer. Tacticity refers to the orientation of the polypropylene methyl (CH3) group where “iso” polymers are restrained to the molecule’s same side and “syndio” polymers to alternate sides.

Polypropylene homopolymers are pure products that are fabricated using only polypropylene resins while copolymers include an additional plastic material to form a product blend that will modify resulting properties. In example, polyethylene is commonly used within polypropylene copolymer synthesis to increase polymer elasticity. Additives are frequently included during polypropylene manufacture to alter end characteristics such as color, flexibility and resistance to the effects of sunlight UV exposure.

Polypropylene Characteristics & Properties

In its pure polymerized form, polypropylene is a white, highly crystalline solid with a molecular weight that increases with increasing length of the polymer chain. Pure polypropylene, as well as UV resistant PP, is considered non-toxic and certified per FDA, ANSI, NSF requirements for food contact, consumables and drinking water handling. Additives that modify color and rigidity can affect these certifications. PP that is not stabilized with titanium dioxide, carbon black, or similar protective antioxidants will be susceptible to ultraviolet (UV) degradation.

As a plastic, polypropylene has an effective plastic deformation toughness rating, increased fatigue resistance and excellent insulation properties against electrical conductance and thermal energy transfer scenarios.

The range of acceptable hot, cold temperature exposure is dependent on the specifics of PP production as well as the extent and type of additives. In general, polypropylene has a melting point that ranges between 266 to 340°F (130 to 170°C). The maximum temperature range for continuous polypropylene service is 212F up to 266°F (100 to 130°C), and its minimum temperature range is -4 to 14°F (-20 to -10°C), with the range highly dependent on the base polypropylene’s specific formulation. For most cases, the recommended continuous operating temperatures range is 0 to 180°F for polypropylene storage tanks.

The collective properties of polypropylene produces a durable, long service material option that is well suited for use with modern commodities, food stuffs, chemical exposures as well as high and low temperatures for many scenario applications.

How is Polypropylene Used

Next to polyethylene, polypropylene ranks among the top five most used plastics throughout modern societies in the world. As polypropylene is used in product manufacture, plastic granules and any colorants or additives are heated to liquefaction to form molten resins that are extruded, injected or molded to fabricate the wide assortment of products commonly made from polypropylene.

The number of markets, industries, sectors and items that utilize polypropylene is a fairly extensive and wide-reaching list. The packaging and container handling industry accounts for the greatest percentage of PP use from thin films to plastic bags to bulk chemical storage containers. Polypropylene is often used in the chemical process industry, in healthcare, pharmaceutics and laboratories, construction materials, and in general consumer products.

Additional polypropylene production scenarios include its use for plastic parts involved in electrical wiring and components, general equipment, appliances, automobiles, upholstery, fabrics, plumbing, and common household items.

Polypropylene Takeaways

Polypropylene is one of the world’s most implemented, engineered and versatile synthetic materials. It belongs to the family of plastics with polyethylene, PVC and ABS. Polypropylene is most often used in the fabrication of containers and handling materials such as bags, tubing and pipes. It is a common component in plastic pieces that are associated with industry equipment, consumer items, and automobiles.

Polypropylene plastic is well known for its chemical resistance, high purity food grade use and tolerance to elevated and depressed service temperatures. If looking for polypropylene handling containers or components with a full range of customizable options, consider our product offerings. We provide only the industry’s best polypropylene products in terms of material quality, warranty and engineering know-how that have been made by North America’s leading manufacturers. Contact us with your questions or request a custom fabricated polypropylene tank product today.