Chemical injection tanks are used to manage the precise and controlled handling of chemicals across a variety of industries. These specialized tanks are designed to store chemicals and be used with accurate dispensing equipment to deliver optimal performance in processes that require specific dosages of additives or treatments. From preventing corrosion in pipelines to treating water systems and improving oil wells to agricultural yields, chemical injection tanks are an essential tool in many industrial chemical storage and applications.

The importance of these chemical tanks reaches beyond just storage — they are used to maintain operational efficiency, safeguard equipment, and ensure regulatory compliance. Without reliable chemical injection systems, industries could face challenges such as inconsistent outputs, increased operating costs, or safety risks.

This guide aims to provide a detailed exploration of what chemical injection tanks are, how they function, and where they are used. By examining their components, benefits, design features, and industry applications, we will equip you with knowledge to understand their significance and make informed decisions regarding their use. Whether you operate in oil and gas, agriculture, or water treatment, this guide will highlight how chemical injection tanks can meet your operational needs.

Understanding Chemical Injection Tanks

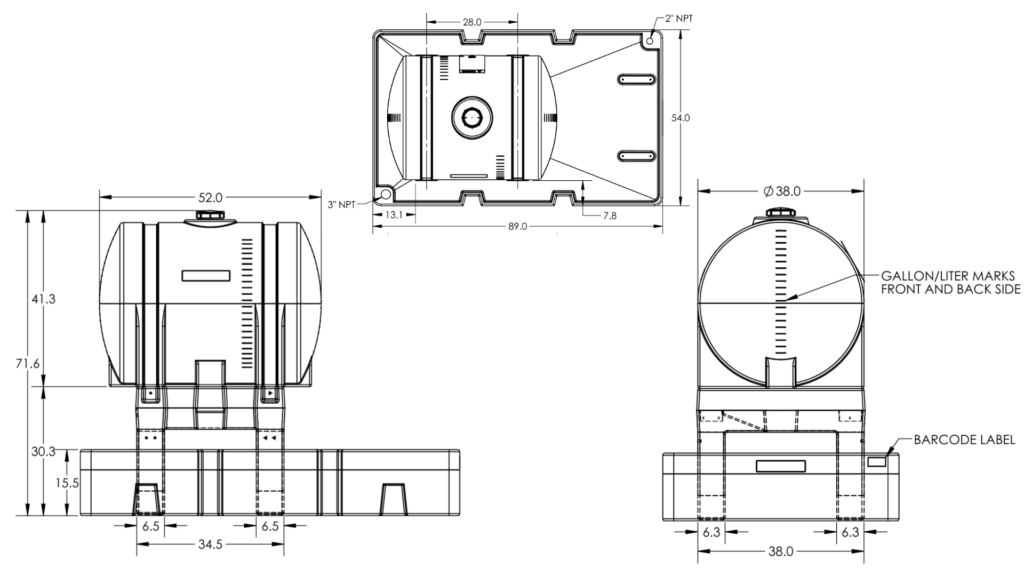

Chemical injection tanks are a specialized product set designed to provide secure chemical storage and precise dispensing capabilities. These systems typically include three main components: a horizontal leg tank, an elevated tank stand, and a covered spill containment basin. Together, these ensure the stability and safe handling of liquids for chemical injection systems. The tanks are intended to be used with pumps and regulators to introduce chemicals in measured amounts to achieve specific process goals and optimization.

Built from high density virgin polyethylene resin (HDPE) and rotational mold manufacturing, these tanks are seamless, resilient, and reliable. HDPE material’s natural resistance to impacts, chemical and environmental corrosion as well as temperature extremes, combined with UV inhibitors, makes these tanks suitable for year round indoor and outdoor use. Additionally, the tanks are made from FDA approved materials and can safely store potable water if needed.

A typical chemical injection system works by drawing chemicals from the tank, measured by a pump, and injecting them into pipelines, equipment, or other systems through the use of pipes or hoses and various fittings. For example, in oil and gas applications, chemical injection tanks introduce corrosion inhibitors to extend the lifespan of pipelines. Similarly, water treatment facilities rely on these tanks to dispense disinfectants like chlorine for consistent water quality. Their ability to provide precise operation minimizes chemical waste, supports regulatory compliance, and improves overall stability.

Parts of a Chemical Injection Tank

The Tank

At the core is the horizontal leg tank, rotationally molded from high density virgin polyethylene resin. This seamless design provides strength and eliminates common vulnerabilities from weak joints. The tanks are a transparent white color with gallon indicators for easy monitoring of liquid levels. As leg tanks, they have molded-in legs that provide free-standing stability.

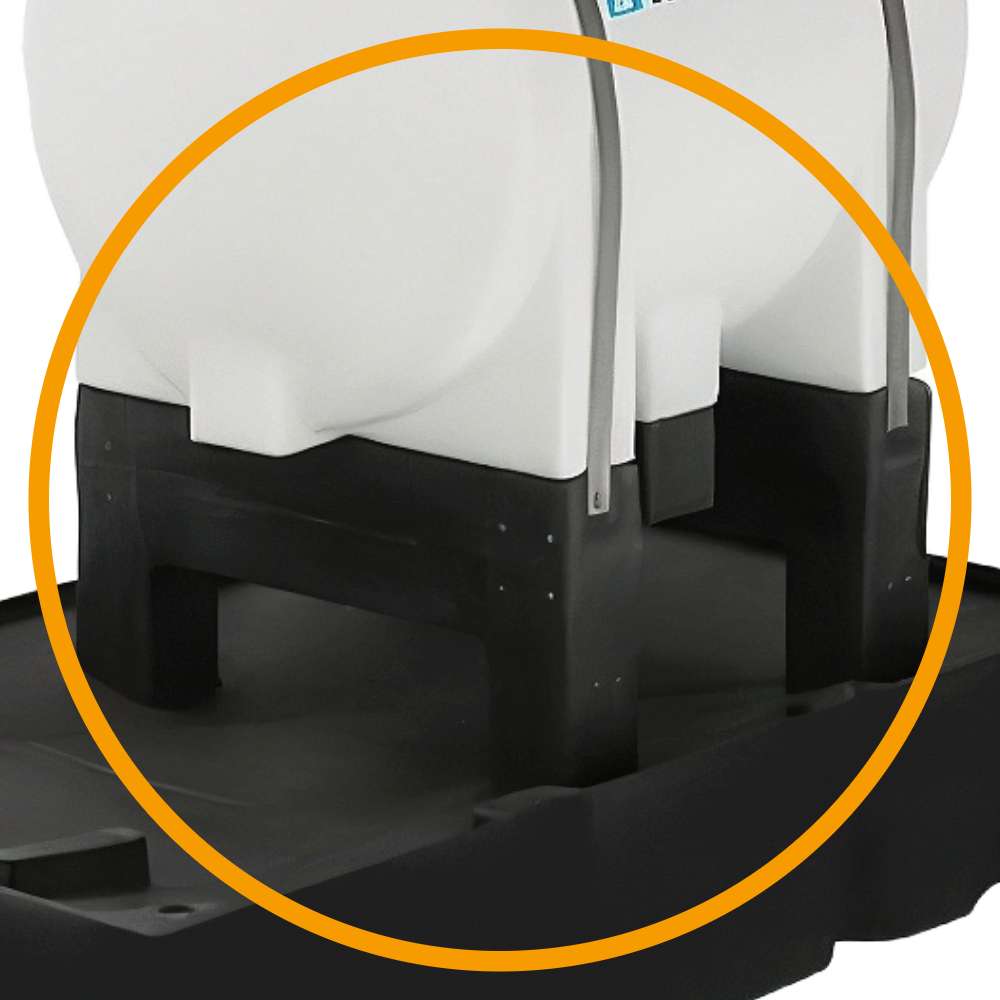

The Stand

Chemical injection tank kits, like those offered by the National Tank Outlet, come with a tank stand. This sturdy tank stand supports the horizontal leg tank and elevates it above the ground to allow gravity-driven fluid flow and improve visibility. Additional steel support bands can be purchased to firmly secure and mount the tank to the stand if tipping or movement is a concern.

Injection Pump

The pump serves as the engine of a chemical injection system, controlling the flow and pressure of the chemicals. Pumps allow precise dosing that can be tailored to an operation’s needs. Injection pumps can often be adjusted to deliver exact volumes, allowing direct management and control of fluid flow and delivery.

Note, our chemical injection tanks do not come standard with an injection pump. For a wide selection of liquid pumps, we recommend the company Sprayer’s Supplies and their extensive catalog.

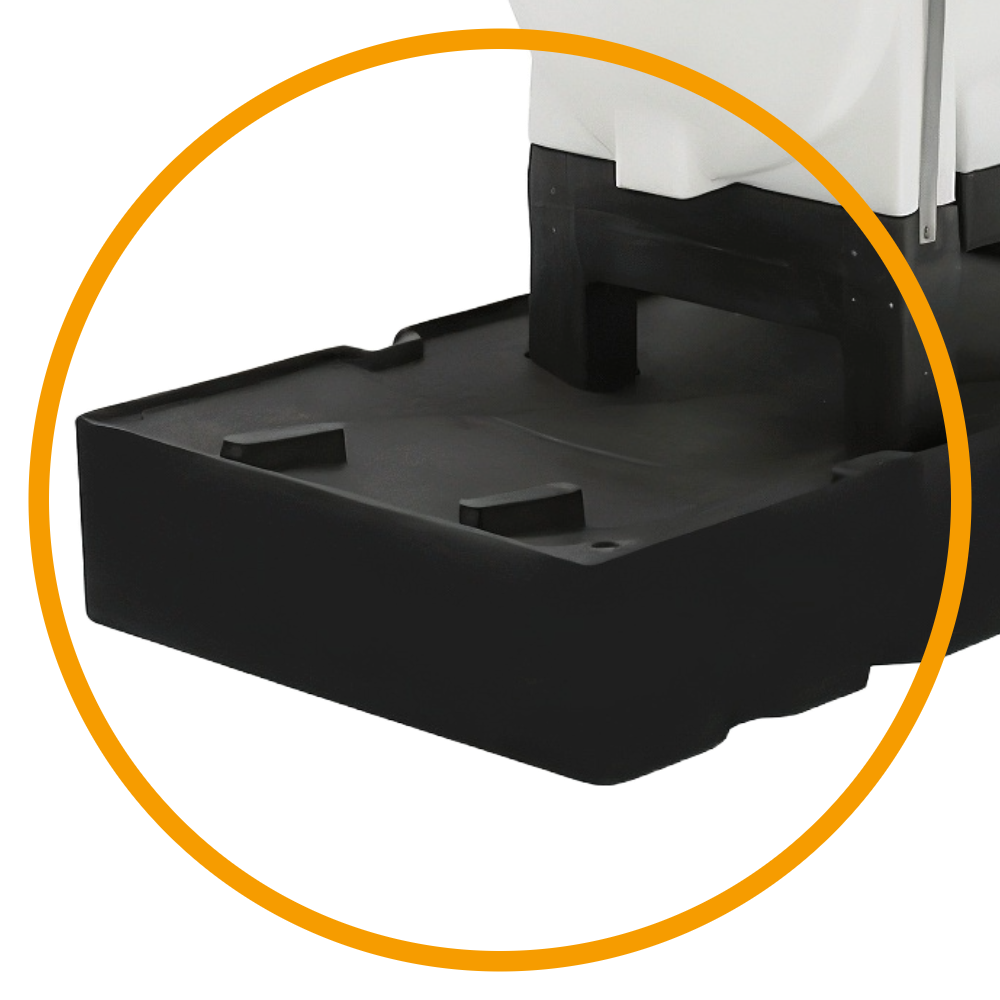

Containment Basin

The covered containment basin is a critical feature that safeguards against spills and environmental contamination. Designed to accommodate the tank’s size, the spill basin prevents debris and wildlife from being able to access any chemicals that may have leaked from connections.

Accessories

Tubing, pipes, valves, fittings, and monitoring devices complete the system by directing chemicals from the tank to the injection site. Optional fittings, such as the 316SS bolted fitting with MNPT nipple and XLPE gasket, and others are available to complete connections to the tank.

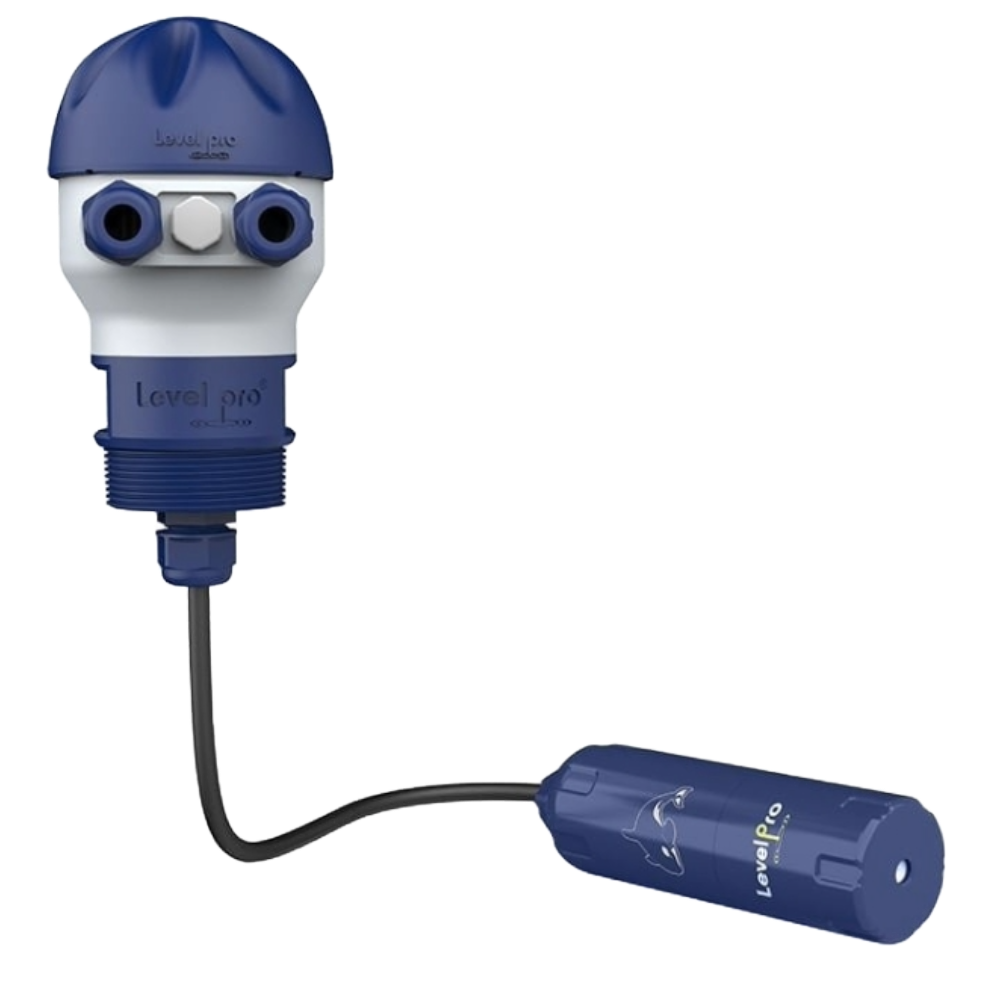

Monitoring systems such as level sensors can track chemical usage, levels, and flow rates to ensure accurate dosing, prevent waste, and alert when refilling is needed.

Common Uses and Applications

Industries that Use Chemical Injection Tanks

Chemical injection tanks are indispensable across multiple industries where precision and control of chemical handling are essential. Their versatility allows them to contribute to process efficiency and better outcomes across applications. Below are the key industries that rely on or that benefit from these specialized tanks:

Oil and Gas

The oil and gas industry frequently uses chemical injection systems to protect their pipelines and equipment. For example, corrosion inhibitors are added via chemical injection tanks to protect pipelines from degradation that can be caused by harsh working environments such as high pressure or high salinity. Additionally, demulsifiers are injected to separate water from oil to benefit the refinement process.

Water Treatment

Water treatment facilities employ water treatment tanks and injection tanks to introduce chemicals like chlorine or pH adjusters into systems. This process ensures water is safe for consumption and meets quality standards. For example, chlorine injection is often used to disinfect municipal water supplies, while other chemical injection tank setups may be used to neutralize contaminants in industrial effluent before discharge.

Agriculture

Agriculture relies on agricultural storage tanks to store and deliver fertilizers, pesticides, and herbicides with precision. These tanks are used along with injection tanks to pump nutrients into irrigation systems to improve crop yield and quality. Chemical injection systems also help to evenly distribute pesticides and herbicides while minimizing waste.

Practical Applications

Chemical injection tanks extend their usefulness by being suitable for practical applications in other, specific industrial goals. For example, in offshore oil rigs, compact chemical tanks are equipped to handle substantial environmental stress while reliably delivering anti-corrosion agents. Similarly, industrial application may utilize large capacity tanks to manage high volume chemical dosing for onsite activities. In high precision manufacturing, chemical injection tanks allow metered control of necessary chemicals and mixtures for production in small and large commercial operations.

Each of these industries highlights how chemical injection tanks provide a link between the chemicals used and the goals achieved. Their strategic use enhances safety, efficiency, and compliance, making them a valuable component across these sectors.

Benefits of Using Chemical Injection Tanks

Precision and Control

One of the largest advantages of chemical injection tanks is their ability to provide a dedicated setup and station for precision dispensing of application chemicals. Industries often require exact chemical dosages to maintain workflow quality, efficiency, and safety. These tanks work hand-in-hand with chemical pumps and monitoring systems to deliver accurate amounts and consistent results. For example, in water treatment, overly high or low chemical levels could compromise water quality. By using chemical injection tanks, workflows can become more controlled, reliable, and experience minimal deviations.

Durability and Safety

Chemical injection tanks are built from materials capable of withstanding hardworking industrial applications. High density polyethylene (HDPE) is commonly used due to its durability and overall resilience. This material is non-reactive and chemically strong, allowing safe handling of highly corrosive or hazardous chemicals like acids, caustics, and disinfectants. Chemical injection tanks are often designed with safety features such as secure lids and bulkheads, spill containment, and monitoring devices to protect operators, reduce environmental risks, and ensure regulatory compliance and long term reliability.

Efficiency

Chemical injection systems are designed for efficiency, engineered to reduce waste by minimizing chemical overuse and preventing leaks. This saves costs, minimizes environmental impact, and automates chemical delivery to save time and labor. Whether used in oil pipelines, irrigation systems, or water treatment facilities, chemical injection tanks can improve overall operations and productivity.

Key Benefits at a Glance:

- Accurate Chemical Dosing: Allows precise delivery, consistent results, and efficient workflows when used with dosing and metering equipment.

- Corrosion Resistance: Built from durable materials to withstand tough environments and protect stored chemicals.

- Optimized Chemical Use: Minimizes waste and associated costs, promoting optimization and sustainability.

- Automated Systems: Streamlines applications and reduces manual labor and errors.

Design Features and Customization Options

Material

Construction material plays a key role in the performance and service life of chemical injection tanks. High density polyethylene (HDPE) is one of the most commonly used materials due to its excellent chemical resistance, low weight, and cost effectiveness. HDPE tanks can handle a broad range of chemicals, making them suitable for various industries. These tanks are particularly effective in environments where exposure to harsh substances like acids, bases, or salts is expected.

Tank Sizes and Capacities

Chemical injection tanks come in several sizes to match different application needs. Small scale systems, such as those used in agricultural operations or localized water treatment processes, may require smaller capacities such as 65 gallon chemical injection tanks. These compact tanks are easy to transport and install, making them ideal for portable or temporary setups.

On the other end of the spectrum, large capacity tanks up to 335 gallons are ideal for heavy duty industries like oil and gas or municipal water treatment. These tanks are designed to safely handle substantial chemical volumes. Intermediate sized tanks, 125 gallons and 225 gallons, are popular for mid scale operations where a balance of capacity and mobility is needed.

Custom Features

Customization is a key part to make the most out of modern chemical injection tanks and match them to unique industrial processes. One common customization is the addition of specific fittings, including drain valves, bulkheads, and flanges to integrate with delivery systems and pipe networks.

Configurations such as double tanks or level sensing accessories offer additional flexibility. Double tanks, for example, allow operators to store and dispense two different chemicals from a single setup. Similarly, level sensing devices or gauges help monitor chemical levels in real time, which can improve control over operations and prevent overfilling or shortages.

Selection and Maintenance Guide

How to Choose the Right Chemical Injection Tank

Select the right chemical injection tank to ensure workflow efficiency, safety, and long term functionality. Here are the key points to guide you on how to choose the right option:

- Chemical Compatibility: The chemical to be stored or injected must be compatible with the construction material of the tank, fittings, and equipment. Always confirm chemical compatibility and resistance with high density polyethylene (HDPE) prior to purchase and use.

- Size and Capacity: Consider the volume of chemicals your operations require as well as use and refill frequencies. Smaller portable tanks may be sufficient for applications like agricultural fertilization, while higher capacity tanks may be better for heavy duty industries such as oil and gas. Always ensure the tank size aligns with your chemical usage rates to help avoid underuse or overcapacity issues.

- Operational Needs and Environmental Conditions: Assess if the tank will operate under extreme temperatures, high pressures, or in outdoor environments. Tanks with additional features, like UV protection or reinforced bodies, may be necessary in such setups.

Questions to Ask Before Purchasing:

- What chemical(s) will the tank store or inject, and are they compatible with the material?

- How much chemical volume will the tank need to accommodate daily, weekly, or monthly?

- Are there any regulatory or safety requirements specific to the operating environment?

- What are the connection or system integration needs (e.g., pump, fittings, valves)?

- Will the tank be stationary or need portability for field use?

Maintenance Best Practices

Proper maintenance extends the lifespan of chemical injection tanks while ensuring safe and efficient operations. Follow these best practices:

- Routine Cleaning and Inspections: Clean the tank regularly to prevent chemical buildup, contamination, or corrosion. Use cleaning agents approved for the previously stored chemical. Perform visual inspections for cracks, discoloration, or other signs of wear, especially along the tank seams and fittings.

- Test Equipment and Connections: Frequently check pumps, valves, and gauges for proper functioning. Replace worn out or damaged parts immediately to prevent leaks or system failures.

- Protect Against Environmental Wear: If the tank is outdoors, consider shielding it from UV exposure and extreme weather conditions. Many tanks feature UV resistant compounds that prolong durability against sunlight effects.

- Monitor Chemical Levels: Install level sensors or gauges to track stored chemical levels and avoid running dry to prevent interruptions in daily operations.

- Scheduled Professional Maintenance: Have the system evaluated regularly by professionals who can inspect for structural integrity, ongoing chemical resistance, and system performance.

Quick Takeaways:

- Choose tanks based on chemical compatibility, size, and work needs.

- Verify the tank and fittings are ready for system connections before purchasing.

- Clean and inspect tanks regularly to prevent buildup or damage.

- Monitor all fittings, seals, and valves for wear and promptly replace when needed.

Regulations and Compliance

Regulatory Requirements for Chemical Storage Tanks

When working with chemical injection tanks, adhering to regulatory standards is essential for safety, environmental stewardship, and operational success. Various government and industry specific organizations have established guidelines to ensure the proper storage, handling, and disposal of chemicals depending on the type of chemicals and industry. Two major entities that regulate chemical storage are the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA).

- EPA Guidelines: The EPA enforces strict provisions under regulations such as the Clean Water Act (CWA) and the Resource Conservation and Recovery Act (RCRA). These rules ensure that tanks storing hazardous chemicals are designed to prevent spills, leaks, and contamination of groundwater or nearby ecosystems. Secondary containment systems, such as spill basins or double walled tanks, are often required to mitigate potential environmental hazards.

- OSHA Regulations: OSHA focuses on workplace safety, mandating that chemical storage tanks operate in ways that reduce risks of exposure, fire, or other hazards to employees. Regulations include specifications for labeling tanks, using appropriate protective equipment, and maintaining proper ventilation around storage areas. Tanks must also be compatible with the chemicals they contain to prevent dangerous reactions or failures under OSHA’s Hazard Communication Standard.

- Additional Standards: Beyond EPA and OSHA, other organizations, such as the American Society for Mechanical Engineers (ASME) and the American Petroleum Institute (API), set performance and safety benchmarks for chemical tanks. These guidelines often address structural integrity, material compatibility, and pressure handling.

Importance of Compliance

Meeting regulatory standards isn’t just about following the law – it’s necessary for operational efficiency and risk management. Non-compliance can lead to severe penalties, including fines, facility shutdowns, or damage to a company’s reputation. Using chemical tanks that meet compliance can ensure the safety of employees, the public, and the environment.

Key Compliance Considerations

When choosing a chemical injection tank, consider the following:

- Confirm that the tank material is certified safe for the specific chemicals involved.

- Verify the tank includes required safety features, such as secondary containment and measurement devices.

- Ensure the tank complies with rules specific to your industry, which vary based on the chemicals stored and work environment.

- Conduct regular audits and maintenance to ensure continuing compliance with EPA, OSHA, and local regulations.

The Role of National Tank Outlet in Chemical Injection

National Tank Outlet stands as a trusted leader in supplying high quality chemical tanks including chemical injection tanks that have been engineered to meet a wide range of industrial needs. With a reputation for durability, safety, and precision, our tanks support businesses across various applications by providing reliable chemical handling and storage solutions.

Expertise and Product Range

National Tank Outlet offers an extensive selection of chemical injection tanks, chemical tanks, and double wall tanks to match different industries and applications. Our product lineup includes tanks made from high density polyethylene (HDPE), cross-linked polyethylene (XLPE), polypropylene (PP), and tanks made from fiberglass reinforced plastic (FRP) available on request. Beyond standard tanks, we may be able to provide customizable options, including pre-installed fittings, level monitoring accessories, and secondary containment systems.

Complementary products, such as pumps, fittings and valves, and mixers, further extend the utility of National Tank Outlet’s chemical tanks.

Industries Served

From agriculture to water treatment, oil and gas, and chemical processing to food and beverage production, National Tank Outlet offers products suited for many clients. Agricultural businesses rely on our injection tanks to accurately distribute fertilizers and pesticides, while municipal water treatment facilities use our tanks for safe chlorine storage and injection. Similarly, the oil and gas sector benefits from our high quality injection tanks to handle corrosive inhibitors and other harsh chemicals used in maintaining pipeline integrity.

Why Choose National Tank Outlet?

When you choose National Tank Outlet, you’re getting chemical tanks designed with safety, compliance, and efficiency in mind. Our team is here to help you every step of the way — whether it’s finding the right tank or customizing one to fit your needs. We’re committed to providing top quality solutions and making the process as smooth as possible for you.

Takeaway

Selecting and maintaining the right chemical injection tank is essential for operational success. Here’s a quick recap of key information:

- Choose the Right Tank: Chemical compatibility, size, and workflow needs are key factors to consider. Always verify that the tank meets industry standards and environmental regulations.

- Customization Options: Setting your tank with fittings, sensors, and safety features will improve functionality and align with your specific operations.

- Maintenance: Regular cleaning, inspections, and professional evaluations will extend the lifespan of your tank and ensure safe usage.

- Compliance: Always select tanks designed to align with EPA, OSHA, and other relevant regulations to avoid legal and worksite risks.

Act Today

Explore the full range of National Tank Outlet chemical tanks and accessories to find the ideal solution for your application. With years of industry experience and a dedication to quality, National Tank Outlet provides high quality injection tanks that deliver performance and peace of mind.

Visit our web site or contact our knowledgeable team for personalized assistance. Regardless of your business or industry or application needs, National Tank Outlet has the expertise and products you need to succeed – reach out today.