In rainwater harvesting, a rain catchment system and tank are each made with a select set of parts, equipment, and accessories. In this Rain Tanks Series: Tank Definitions, we will look at and define the different parts of a standard rainwater collection tank. This post will focus primarily on vertical, above ground polyethylene storage tanks, like those found here.

The post is intended for do-it-yourselfers (DIYers) and fledgling rain harvesters new to the practice. If this sounds like you, “Welcome,” and it’s great you’re here and that you have an interest in practicing rainwater harvesting as an alternative water supply, for conservation, and together for our environment.

Parts of a Rain Tank

There are five (5) main parts to a complete, standard polyethylene rain tank. These five parts are the cistern itself, the manway, the overflow, bulkhead fitting(s), and the base foundation.

The Cistern

The word cistern is an old term that has been around and used throughout history, and refers to a watertight vessel or area used to store and provide water as needed. A cistern can be above ground or underground, small or large in volume, made of plastic, metal, or the earth and earthen materials. Here, we are discussing bulk volume, above ground storage tanks made from linear polyethylene as it is one of the most common and modern material options for rainwater harvesting.

Plastic rainwater cisterns are manufactured from what is known as linear high-density polyethylene, sometimes abbreviated HDPE, HDLPE, or poly. While this may raise questions or concerns for health-conscious individuals and environmentalists, polyethylene rainwater tanks are made using only premium quality materials that have been approved by the U.S. FDA (Food & Drug Administration) for health.

Many polyethylene rainwater cisterns are also additionally certified to ANSI/NSF 61 standards for potable drinking water. The American National Standard Institute (ANSI) and National Sanitation Foundation (NSF) Standard 61 is a nationally recognized approval guaranteeing a product is safe for drinking water. This means a poly cistern is 100% safe and approved for the long-term storage and provision of clean, drinkable water and will not affect water quality in any way.

The cistern serves as a reservoir in rainwater harvesting to store rain as it is being collected and hold the rainwater until it is time for it to be used. Above ground poly rainwater cisterns most often range in size from 100 gallons to 10,000 gallons of water storage capacity. They are traditionally made and offered in two types: cylindrical and slimline. Cylindrical rain tanks are circular in shape and are an overall good, go-to choice for rainwater harvesting. Slimline rain tanks are also known as doorway tanks and are rectangular in shape that makes them ideal for placement along walls and fences, in locations cylindrical tanks may not fit, and simply to save space.

The Manway

In many rainwater harvesting setups, the manway serves as the main entry point for rainwater flowing into the cistern for collection. By definition, the manway is the opening on the top of the tank used to allow access to the tank interior for inspection and maintenance. In rainwater harvesting, the manway is commonly used as the primary inlet for collecting rain as it flows through the system to the cistern.

Rain tank manways are often larger in size to provide a better opening for rainwater inflow, making system setup easier and reducing potential water loss from spillage. Many polyethylene rain tanks available for purchase commercially include a tank screen accessory designed to fit within the manway and filter out debris in the rainwater.

The manway does not have to be used as the rainwater collection inlet. A rainwater harvesting tank and system can have piping directly plumbed to the storage cistern at a bulkhead fitting or through the tank wall by way of drilling a hole.

When discussing the manway, it should be mentioned that no one other than a licensed professional should ever enter a storage tank for any reason due to safety hazards.

The Overflow

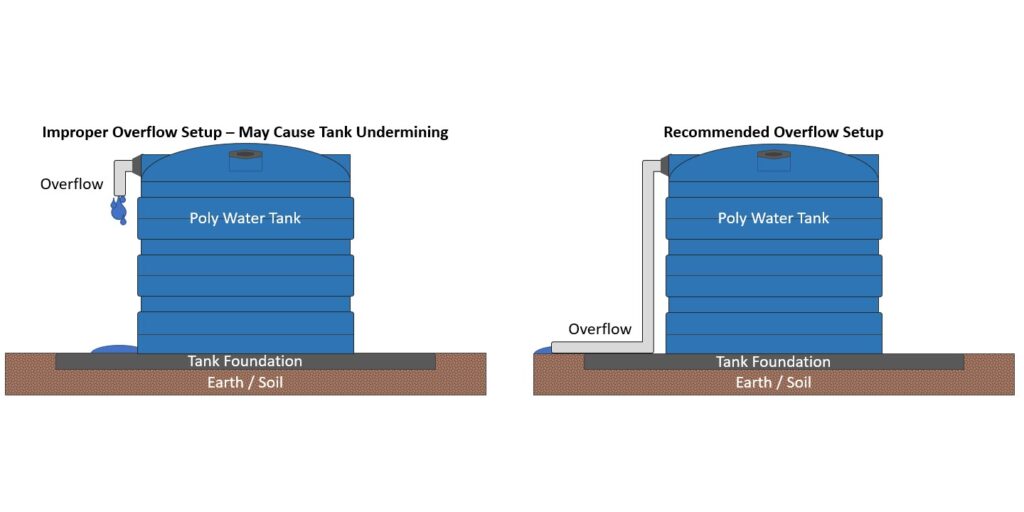

In a rainwater harvesting tank, the overflow is an important component used to manage excess water whenever the tank becomes full. The overflow is simply an open port located near the top of the rain container that provides a dedicated location for excess rainwater to “overflow” from the tank.

The overflow port allows excess water to be managed in a controlled way. Without an overflow, excess water would pour out from the manway or any other opening and flood around the tank base.

Proper installation and use of an overflow will direct the excess rainwater away from the tank base as well as the foundation of any nearby structure. This recommendation exists to prevent erosion around the rain tank’s foundation and to prevent any damage that can occur over time from large volumes of water concentrated at a set location.

A tank overflow port is a pre-installed standard on most rain tanks for sale and comes ready for setup and use. The tank overflow port is often either 2” or 3” in diameter and can be easily connected to PVC piping to run the overflow water to wherever desired. Ideally, the tank overflow will put the extra water to good use watering nearby landscaping, lawns, or rain gardens.

For large rainwater harvesting setups, the overflow can also be used to connect multiple rain tanks together. In a connected rain tank setup, the excess water from the first tank will overflow and be collected by the second tank rather than being discarded.

For rainwater cisterns without an overflow, a tank outlet kit can be purchased and easily installed to properly manage rainwater overflow.

The Bulkhead Fitting(s)

By definition, the bulkhead fitting is a through-wall plumbing fixture used to make pipe connections and allow liquids to flow from one location to another through a wall by means of a specified, leakproof hole, which is the bulkhead fitting. A bulkhead provides a secure location for connecting pipes, valves, and/or hoses to a rain tank so harvested rainwater can be easily withdrawn when needed.

Most commercially available rainwater tanks include one (1) or two (2) bulkhead fittings pre-installed and ready for use.

- Rain tanks with only one bulkhead will feature the fitting near the base of the tank for distributing and using the collected rainwater.

- Tanks with two bulkheads may feature two at the base where the lowest fitting can be used as a drain and the higher fitting in water withdrawal.

- Other tank with two bulkheads may have one at the base and one near the top of the tank for use as a rainwater inlet or for use in connecting multiple tanks together.

Many standard rain tank bulkheads are 1” in diameter with NPT style threads for making connections. NPT stands for National Pipe Thread (or National Pipe Tapered) and means the plumbing part uses threads to connect to other NPT style plumbing. Bulkheads with larger diameters and those with different connection styles can be used to replace standard rain tank bulkheads to allow use with larger piping and specific plumbing connections, such as the garden hose fitting adapter.

The Base Foundation

In rainwater harvesting, the base foundation refers to the ground and material type the rain tank is installed on. Common foundation types for bulk volume polyethylene rainwater collection tanks include pea gravel, concrete, and directly on the earth’s surface.

Pea gravel is a top recommendation for a rain tank foundation. Pea gravel is suitable for small to large volume collection containers, allows drainage, prevents standing water, is good for first flush device drainage, and can be considered aesthetically appealing. When choosing pea gravel, use rocks no larger than 1-1/2″ in size, consider adding a wooden border to ensure containment and prevent erosion loss of gravel over time. Always firmly compact the gravel evenly prior to tank placement and use.

Concrete rain tank foundations provide the best weight support, long lasting strength, and are suitable for all rain tank volumes. A concrete foundation will not erode but also does not allow for drainage, which can lead to pooling of water.

Directly on the ground is a common choice for small to medium size rain tanks. The ground provides even weight distribution, firm support, and allows for drainage but the drainage can be slow with the possibility of soil retention and pooling water. When choosing a ground foundation, ensure overflow water is discharged away from the tank and foundation to prevent any potential erosion. Normal weather events can cause erosion to a ground foundation over time and the base should therefore be contained within a support box and periodically inspected. Due to the potential for erosion, ground foundations are not recommended for large volume rain tanks.

Another common rain tank base is to install the cistern on a raised platform, as shown here. A raised platform base foundation removes some of the concern with erosion and can make the tank easier to reach for filling of watering cans and improve how quickly water flows from the cistern.

Takeaway | Tank Definitions

The main parts of a rainwater collection container are the cistern that functions as a reservoir, the manway that allows for access, the overflow to control excess rainwater, the bulkhead fitting that allows water flow and withdrawal, and the foundation that supports the tank. It is our hope that knowing the working definitions to the common parts of a rainwater tank will help in the overall understanding of rainwater harvesting, the function of a tank’s different parts, how the parts work together, and will overall help in the planning of your very own system.

If you have questions or are looking for more rainwater information, consider reviewing our blog articles, especially the Rain Tanks Series posts. You can also always contact our professional support team for further questions and help in selecting the right rainwater harvesting equipment.